The time factor !

The time factor !

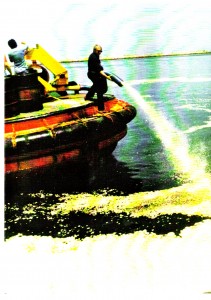

Every one working with spill control & recovery, knows how important it is to fence in an oil spill as quick as possible. Having access to an Upsorb(R) System enables immediate action. You only need three men and a small boat to fill and deploy the Upsorb boom and fence in the spill site in a very short time! The system can be compared to a fireman’s water-hose in a fire situation – fast and efficient as frontline containment action before other more time – consuming methods may be deployed.

Using the Upsorb System

Basic Upsorb foam is manufactured in 1.3 m3 blocks to make the system flexible.Typically the blocks are packed along with the flocculating machine and boom fabric in a 20 foot container. The blocks are cut and ground in an Upsorb LS3 Machine and made into booms for immediate deployment or for storage. In an emergency situation approx. 400m of boom per hour can be filled & deployed.

The Upsorb flocculating machine LS3 has a diesel driven engine which is an advantage when using it in, for example, oil or gas refineries. The LS3 machine is easy to work and the feeding of Upsorb foam can be done either by the fan or the screw device.

When using the screw device, the operation is more or less dust free. Wheels on the machine makes it easy to move on flat ground

Ready – Made Boom

We also supply readymade booms in standard packing of 3 meter length X 50cm diameter, fitted with snap on hooks. Custom booms of various lengths, with rope connectors and booms with skirts and chain (to serve as ballast) can be made to order.

.